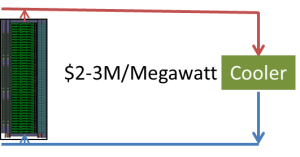

Hyperscale with Cooling Tower or Adiabatic Cooler

The path from hot body to ambient is low in a liquid cooled system so that coolant temperatures of over 40 degree C are acceptable.

As can be seen, the system is very simple, consisting effectively of only a heat gatherer (the rack) and a dissipator. Servers can be cooled year round with dry coolers, adiabatic coolers or cooling towers in many parts of the world.

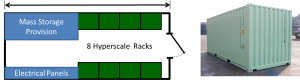

3 Petaflop Container Concept

A 20 foot container could be constructed to hold eight 24″ deep Hyperscale racks while still leaving room for electrical distribution as well as a mass storage system if required. The racks wold be populated with using 1152 450W 2S Servers. Each server would hold two high power CPUs, consuming about 150W apiece (e.g.Intel Xeon E5-2695). The container would require 600kW Power & Cooling.

The estimated cost without servers but including racks,UPS, Genset and Adiabatic Cooler would be significantly less than $2M.

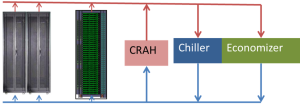

Refit in Conventional Data Center

Adding a hyperscale rack to an existing DC is relatively straightforward. It needs only to be connected to the existing building water system, a relatively simple plumbing job. Alternatively, as the system can use much warmer water than supplied to the CRAHs or rear doors, it could be added in series with the existing equipment. While this would offer greater efficiency, care would be needed to ensure correct flow rates through both systems.

Adding a hyperscale rack to an existing DC is relatively straightforward. It needs only to be connected to the existing building water system, a relatively simple plumbing job. Alternatively, as the system can use much warmer water than supplied to the CRAHs or rear doors, it could be added in series with the existing equipment. While this would offer greater efficiency, care would be needed to ensure correct flow rates through both systems.

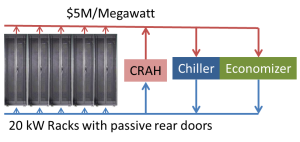

Conventional System

In the conventional data center, the resistance between the heat source and the dissipation point, generally outside air, is not great enough to get sufficient heat flow from hot to cold. The chiller must therefore be used to create a thermal gradient artificially. This can consume between 20% and 35% of the imposed thermal load. In addition, there are two sets of air circulation fans, one in the CRAC (computer room air handler) and the other in the servers.In warmer climates the chiller might be running full time while in more temperate ones, the economizer might dissipate heat directly to ambient without the need for chiller help, cutting energy costs.

In the conventional data center, the resistance between the heat source and the dissipation point, generally outside air, is not great enough to get sufficient heat flow from hot to cold. The chiller must therefore be used to create a thermal gradient artificially. This can consume between 20% and 35% of the imposed thermal load. In addition, there are two sets of air circulation fans, one in the CRAC (computer room air handler) and the other in the servers.In warmer climates the chiller might be running full time while in more temperate ones, the economizer might dissipate heat directly to ambient without the need for chiller help, cutting energy costs.

The illustration shows five 20kW racks which is about the maximum without heroic efforts, and cooled with passive rear doors. These have the advantage of helping lower the system thermal resistance and increase rack capacity from a more typical 10kW.